Lin Plastic Linear Bearings

-

Lin Plastic Linear Bearings

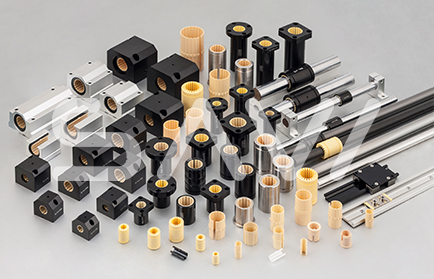

● Maintenance-free self-lubricating plastic linear bearings. Noiseless operation. Suitable for continuous use in extremely harsh environments of dust. Allow to be cleaned Food and Drug Packaging Machinery cleaning fluid.

● Maintenance-free, long-term dry run, no noise;

● Suitable for long-term operation of dust;

● Corrosion-resistant, suitable for cleaning with disinfectant;

● Chute design stronger shaft protection;

● Reduced width to increase the carrying capacity;

MaterialFeatureFriction coefficientWearSize table Download

Slide film performance data sheets

| Common Capability | Twsting Method | Unit | EPX | EPJ |

| Density | ISO1183 | g/cm³ | 1.49 | |

| Color | Black | Yellow | ||

| Max.water absorption,23℃/ 50% | ASTMD570 | [%weight] | 0.3 | |

| Max.water absorption | [%weight] | <0.5 | <1.3 | |

| Dynamic friction /steel | μ | 0.09-0.27 | 0.06-0.18 | |

| Max.PV(dry) | MPa•m/s | 1.32 | 0.34 | |

| E-module | ISO527 | MPa | 8,100 | 2,400 |

| Tensile strength,20℃ | MPa | 170 | 73 | |

| Compressive strength | MPa | 150 | 35 | |

| Max.static pressure of the surface,20℃ | MPa | 90 | 20 | |

| Shore D hardness | ISO2039-2 | 85 | 74 | |

| Continuous work tempreature | ℃ | +250 | +90 | |

| short-time work tempreature | ℃ | +315 | +120 | |

| Minimum operating temperature | ℃ | -100 | -50 | |

| Thermal conductivity | ASTME1461 | W/m•K | 0.60 | 0.25 |

| Max.water absorption,23℃ | ASTMD696 | K-1•10-5 | 5 | 10 |

| Volume resisticity | IEC60093 | Ωcm | <105 | >1013 |

| Surface resisticity | IEC60093 | Ω | <103 | >1012 |

Feature

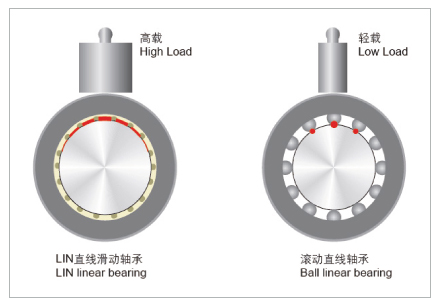

Lin linear bearings high load capacity

LIN linear bearings as a linear slide bearings, working surface is in contact with the surface in the form of shaft surface, and the drive shaft in the form of contact with the surface and linear ball bearing is the dotted line; this determines a greater contact surface LIN series of linear higher than linear ball bearing bearing carrying capacity.

Friction coefficient

LIN linear bearings dry running in the dirt, dust

- LIN linear bearing slide film is a high-performance material designed for dry running and development; special patented design allows the bearings run smoothly dirt, dust or sand, the spiral structure designed so that dirt can fall very quickly into the design the recess, and through constant linear motion was eventually taken out from the recess linear bearing system. The traditional metal linear rolling bearings in the presence of dirt, dust or sand presence will be very prone to stuck, beads and other phenomena ran stuck, stuck phenomenon because even cause the axis to be strained.

LIN linear bearings dry running in the dirt, dust

LIN linear bearing slide film is a high-performance material designed for dry running and development; special patented design allows the bearings run smoothly dirt, dust or sand, the spiral structure designed so that dirt can fall very quickly into the design the recess, and through constant linear motion was eventually taken out from the recess linear bearing system. The traditional metal linear rolling bearings in the presence of dirt, dust or sand presence will be very prone to stuck, beads and other phenomena ran stuck, stuck phenomenon because even cause the axis to be strained.

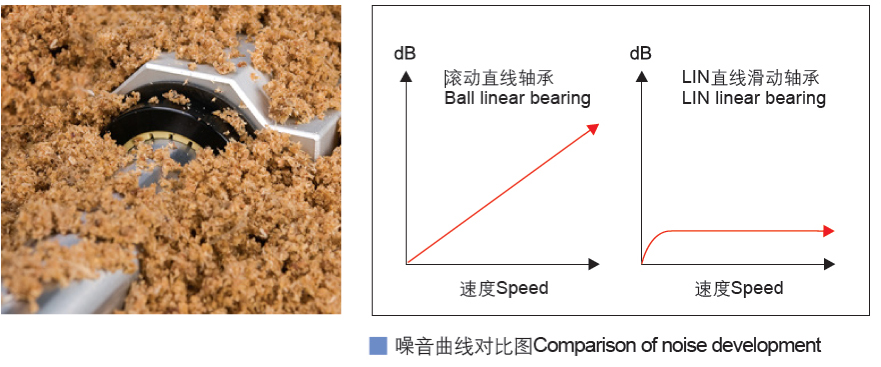

Lin linear bearing low noise operation

Since the metal ball linear bearings and balls in motion the process to keep the impact of noise emitted between the frame body, and this noise will as the speed increases and increased. But LIN linear bearings Face sliding friction design, so can only be issued during the operation sound low friction, running noise is very low.

Wear

Lin linear bearings allow frequent contact with cleaning fluid

LIN linear bearings are often used in food packaging machinery guide mechanism, often by cleaning fluid erosion; years of use as enough proof to resist all kinds of alkaline cleaning solution corrosion LIN Linear bearings As designed, even the whole immersed in running in the liquid medium.

-

-

LIN

Linear slide filmClosure and opening sliding film

READ MORE >>

Standard and short film slide design

-

-

LIN

Fully enclosed linear bearingsEuropean standard design standard

READ MORE >>

Short press-fit design

-

-

LIN

Open linear bearingsOpen design standard

READ MORE >>

Self-aligning design

-

-

LIN

Flange linear bearingRound flange and square flange design

READ MORE >>

Standard and extended design

-

-

LIN

All-plastic linear bearingsAnd bearing pillow block design

READ MORE >>

Standard, short lengthened design

-

-

LIN

Precision linear bearingClosed-precision short design

READ MORE >>

High sewage capacity

Low-cost solution

-

-

LIN

All-plastic linear bearingsFull press-fit plastic closure

READ MORE >>

High sewage capacity

Low-cost solution