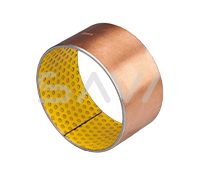

SF-80 Self-lubricating Bearings

- Self-lubricating Bearings Rolling SF-80 boundary lubricated bearings to high-quality low-carbon steel substrate, sintered porous spherical bronze powder, surface modified POM (POM) is firmly fitted. Surface rolling storage pit in order to achieve a good lubrication between the friction. It has good wear resistance and load carrying capacity, anti-corrosion steel back surface coating.

Technical ParametersMetallographyResistanceWearApplicationsDownload

| Max.load | |

| Static load | 250 N/mm² |

| Low speed | 140 N/mm² |

| Rotating,oscillationg motion | 60 N/mm² |

| Max.PV | |

| Short-time work | 3.6 N/mm²*m/s |

| Continuous work | 1.8 N/mm²*m/s |

| Max.PV | -150℃~+250℃ |

| Max.temp | 0.03~0.20 |

| Max.speed | |

| Grease lubrication | 2m/s |

| Periodic greasing | >2m/s |

| Thermal conductivity | 50W(m*K)² |

| Linear cofe. of thermal expansion | 11*10-6*K-1 |

- Note: Where the product can also choose a different base materials according to different conditions, Such as: bronze substrate, a stainless steel substrate, and "lead-free" and other formulations. SF-2Y are environmentally friendly lead-free products, the color is orange yellow, orange, blue.

-

Resistance

SF-80 surface of the polymer chemical resistance, corrosion resistance and therefore it depends on the appearance of the plating layer and steel back. The back surface of copper or tin-plated steel, can effectively prevent atmospheric corrosion; if operating in corrosive media, etc. galvanized steel back can.

SF-80 and wear characteristics under oil lubrication conditions, as follows: it's "running-in" wear rate is very small; seen from the figure line, the applied grease when assembled consumption to a certain extent, the wear rate gradually increases, as shown in dashed lines; if refuel again before the wear rate rises, the wear rate remained stable; when the time is appropriate refueling interval, the material life can be greatly extended. The time interval depends on the fuel accumulated wear.

Grease lubrication: ambient temperature is below 80 ℃, recommended the use of lithium soap grease; ambient temperature above 80 ℃, recommended the use of silicone-based grease; not recommended grease containing EP additives.

Applications

Agricultural equipment: tractors, combine harvesters, crop sprayers, bulldozers, graders, etc;

Automotive industry: power steering pumps, steering gear thrust washer, disc brakes, shock absorbers, door hinges, wiper, recliner chairs, air valve and solenoid valve;

Business office equipment: copiers, fax machines, printers, mail processor and the like;

Hydraulic components and valves: gear pumps, piston pumps, vane pumps, ball valves, butterfly valves, cylinders, fuel tanks and other hydraulic components such as;

Household appliances: refrigerators, air conditioners, vacuum cleaners, sewing machines, washing machines, microwave ovens and fitness equipment;

Logistics and other machinery, packaging machinery, textile machinery, port machinery, mining machinery, forest machinery and all kinds of construction machinery and equipment.

-

-

SF-10

Self-lubricating bearingsSimplify supply design, reducing the oil or fuel is not allowed under repair and is suitable for low speed...

READ MORE >>

-

-

SF-11

Self-lubricating bearingsSF-10 and has the same material properties, and because the bronze bearing substrate to replace the steel ...

READ MORE >>

-

-

SF-20

Boundary lubricating bearingsThe thermoplastic polymer boundary lubrication bearing materials to high-quality ...

READ MORE >>

-

-

SF-40

Self-lubricating bearingsSF-40 material development is to meet the high load, the hydraulic fluid lubrication field, since PTFE wear-resistant materials ...

READ MORE >>

-

-

SF-80

Self-lubricating bearings

Suitable for boundary lubrication long-term use without maintenance;Initial...

READ MORE >>

-

-

SF-FR

Self-lubricating bearings

SF-FR metallic copper mesh to the substrate, the surface attached to the...

READ MORE >>